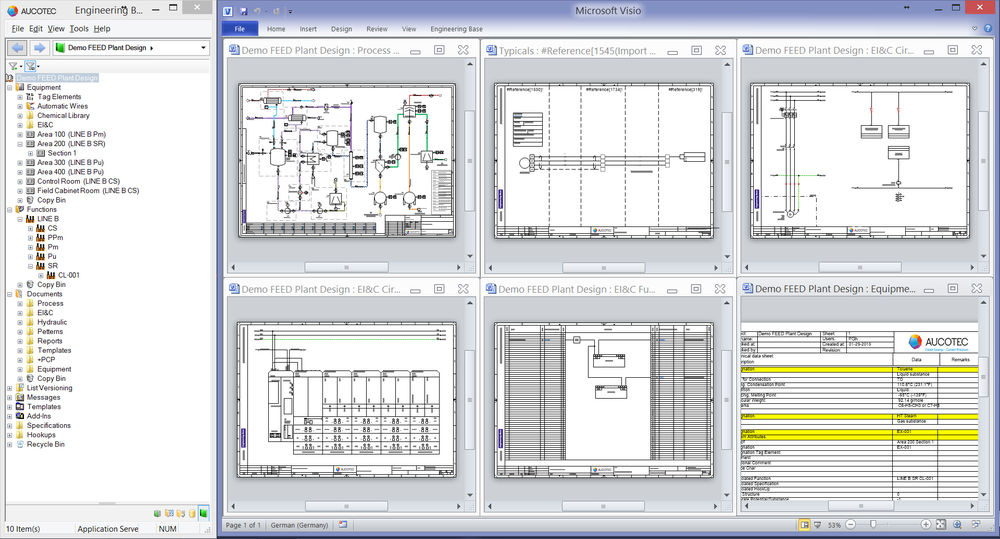

PLANT OPERATORS

Driving force for engineering

Engineering solution makes servicing and revamping more efficient for plant operators

Customized for plant operation in the most diverse industrial sectors: AUCOTEC offers both highly efficient and simple solutions.

The functional scope ranges from asset management via the entire plant life cycle and transparent as-built documentation for revamping up to user-friendly, efficient service solutions that make all changes immediately visible and comprehensible for everyone involved in the process. In addition, big data applications such as predictive maintenance save time and improve data quality with EB.

Sub-segments/topics:

- Process engineering.

- Basic engineering.

- Detail engineering.

- Control engineering design.

- Maintenance.

- As-built.

Your special challenges

- Up-to-date as-built documentation of the plant always required.

- Transparent versioning and revision technology.

- Up-to-date data and documents for daily servicing despite simultaneous revamping measures.

- Revamping with efficient change management of the cooperating disciplines.

- Integration of the revamping project documentation into the existing as-built plant.

- Close link between control and engineering system to avoid downtime in the event of malfunctions.

- Simple, efficient servicing with clear comprehensibility for everyone involved (also SAP, control engineering, and so on).

The optimum process

- Engineering Base (EB) as an ideal cooperation platform: central database for local and remote clients, and scalable architecture.

- The extraordinary openness of EB allows flexible configuration for different requirements without having to customize software.

- The entire design space and usage location concept ensure the replication of the customized wiring harness concept within the entire engineering process.

- Highly consistent parallel work in different steps of the process and disciplines with intelligent synchronization.

- Geometry data integration and optimum data integrity due to bi-directional integration of such 3D systems as CATIA, Siemens NX or Creo.

- Unique full support of the modular design creates a significant increase in efficiency.

- Integrated solution modules from the electrical logic up to the 2D layout in a comprehensive data model.

- Full control of changes and their impact due to unique tracking and revision technology.

- Secure integration of external suppliers by the convenient importing and exporting of engineering data; full change control.

- Support for such standard formats as KBL and VEC.

Embedded in your company IT system

- SAP link for maintenance and servicing organisation.

- 3-D integration for bi-directional data linking of systems.

- Easy Office integration for secure data exchange without proprietary interfaces.

- Open API for integration, for example, in in-house document management and maintenance systems.

- Integration in design systems of control engineering manufacturers to generate program code and support hardware design.