MANUFACTURING PLANT ENGINEERING

Engineering from requirement to optimum

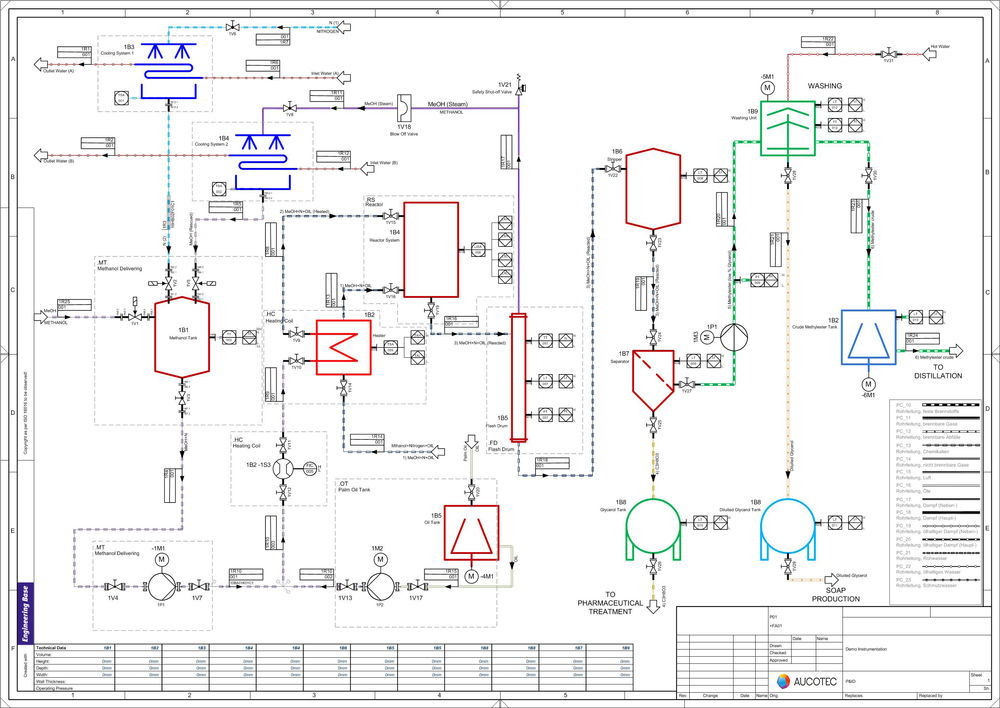

Consistent design software for manufacturing plant engineering

AUCOTEC offers optimum support for highly efficient collaborative engineering tailored to the entire life cycle of manufacturing plants: from requirements engineering via design and installation up to service and maintenance.

The challenges of the Internet of Things, increasing plant complexity and new tasks such as predictive maintenance are mastered by the software platform Engineering Base (EB) with its central data storage, unique openness and particularly clear configuring from standard modular systems. This is how Industry 4.0 operates!

Sub-segments/topics:

- Requirements engineering.

- Project planning.

- Manufacturing.

- Commissioning.

- Service and maintenance.

Your special challenges

- Innovation pressure: a technological lead in the market is becoming more and more short-lived, and reductions in costs and time are becoming increasingly difficult in the plant development process.

- This requires parallel work of the various disciplines for significantly improved exchange of information.

- Globalisation and cost pressure: competitive offers for manufacturing plants even in the growing markets of emerging economies as a prerequisite for sustainable success.

- Coordination of the work of local development teams is thus required in order to implement individual customer requirements on-site.

- Individuality and standardisation: high requirements for customized plants require maximum flexibility of tools and extensive standardisation of components.

- Modular systems with flexible configuration necessary for customized manufacturing plants at mass production costs.

The optimum process

- Engineering Base (EB) as an ideal cooperation platform: central database for local and globally distributed clients with scalable architecture.

- Extraordinary integration ability of EB into PDM/PLM and ERP systems for additional transparency and company-wide solutions which go far beyond engineering.

- Automated "feeding" of control engineering with technical data for more efficient use of Industry 4.0 applications such as predictive maintenance.

- Best communication between the disciplines reduces coordination efforts and errors: integrated solution modules from the inclusion of customer requirements via the plant overview to the individual terminal together with the connected wire inside the control cabinet and all on one shared data model.

- Full control of changes and their impact due to unique tracking and revision technology.

- Secure integration of external suppliers by the convenient importing and exporting of engineering data; full change control.

- Saving time and costs with worksheets for more efficient data processing.

- Highly efficient plant configuration with clear handling of variants and options.

- Direct involvement of additional project participants accelerates cooperation and reduces coordination effort between the disciplines.

- EB Maintenance reduces time for the documentation of changes during and after commissioning.

Embedded in your company IT system

- The closest possible link to SAP and Teamcenter for managing material master data, BOMs and documents.

- Integration of the leading 3-D systems for quick and consistent exchange of device data.

- Open API for integration, for example, in proprietary PDM/PLM and ERP systems.

- Integration of control engineering design systems significantly accelerates transfer of hardware design and signal lists up to parameterization.