HARNESS DESIGN & MANUFACTURING

Everyone pulling together

Engineering software for harness design and manufacturing

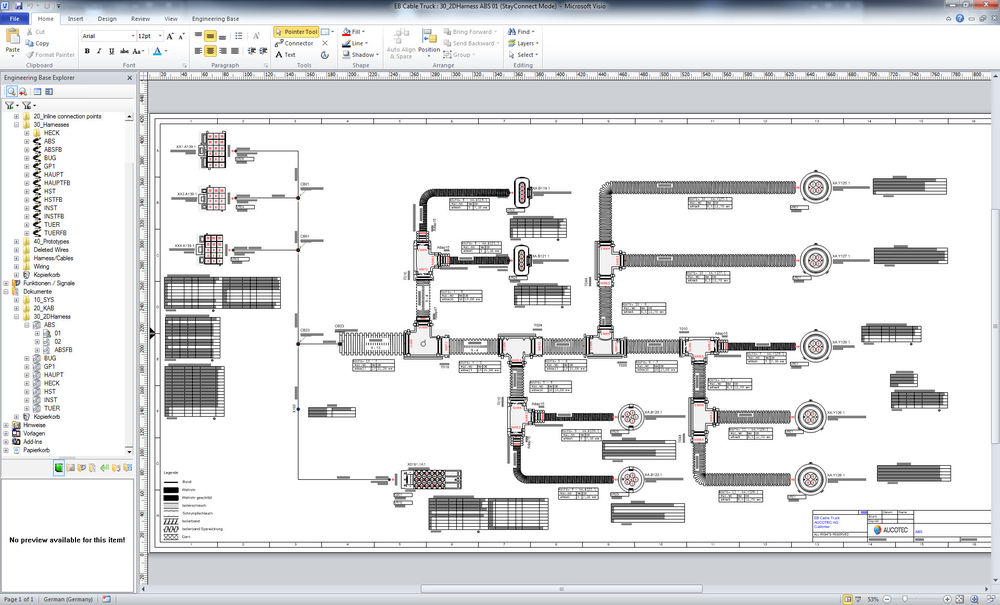

Collaborative, integrative, efficient: AUCOTEC's software platform Engineering Base offers highly efficient solutions for the design and manufacturing of harnesses. Supplier companies in the automotive environment, or also from other industries in which harnesses are produced, can thus map data and processes of different customers in one tool.

They integrate this data perfectly into their own system environment at the same time.

Sub-segments/topics:

- 2-D wiring harness design.

- 3-D integration.

- Template.

- Structuring of manufacturing.

Your special challenges

- Flexible and fastest possible implementation of customer processes and tasks with tailor-made cost estimates.

- High customer expectations for product quality and optimised processes.

The optimum process

- Highest requirements for the processes due to a global market with very different conditions.

- The increasing number of vehicle classes and equipment parameters requires safe and clear variant handling for the many versions of highly complex wiring harnesses (right-hand / left-hand drive, etc).

- Changes to the various vehicle derivatives at different times.

- Ever shorter innovation cycles require quick responses from suppliers to requirements and changes.

- The just-in-time manufacturing of customized wiring harnesses requires a very high level of automation in the preparatory work prior to manufacturing and in the manufacturing process itself.

Embedded in your company IT system

- The closest possible link to SAP and Teamcenter for optimum process integration.

- Easy Office integration for optimum data exchange without proprietary interfaces.

- Open API for integration, for example, in in-house document management and maintenance systems.