SUGAR

"Icing on the cake" also in engineering

Collaborative plant design for the sugar industry

Consistent, international, standard-compliant: AUCOTEC's engineering software offers the sugar industry highly efficient solutions for engineering, operation and servicing of plants.

They permit transparent data management, also for work across sites, throughout all engineering phases from the concept via process design and detail engineering up to manufacturing documentation, servicing and revamping. This includes industry-specific content which is always standard-compliant and can be used internationally.

Sub-segments/topics:

- Process engineering.

- Instrumentation.

- Control engineering design.

- Electrical engineering.

- Maintenance.

- As-built.

The special challenges

- Internationally distributed plant engineering.

- Highly parallel procedure for distributed engineering resources and contractors.

- Support for all standards and regulations required in the target countries.

- Efficient cooperation and control (change management) of the cooperating disciplines in design.

- Always up-to-date data and documents for the daily servicing of existing plants with simultaneous planning of revamping measures.

- Ease of plant operation and servicing to also ensure effectiveness even with less qualified personnel than in Europe/United States.

AUCOTEC solution for the optimum process

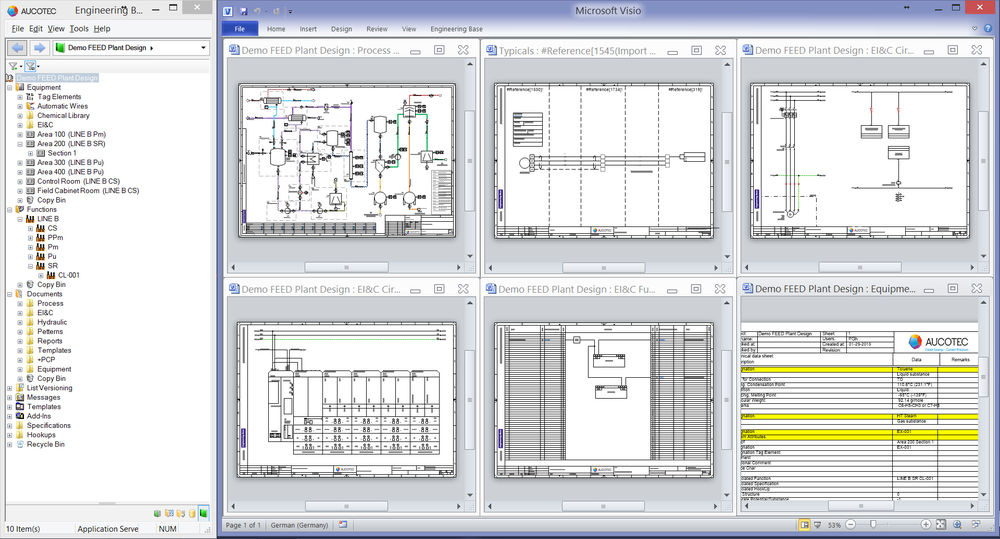

- Engineering Base (EB) as an ideal cooperation platform: central database for local and globally distributed clients, and scalable architecture.

- Exceptional integration ability of EB into PDM/PLM and ERP systems for additional transparency and company-wide solutions which go far beyond engineering.

- Automated "feeding" of control engineering with technical data for more efficient use of Industry 4.0 applications such as predictive maintenance.

- Best communication between the disciplines and external project officers reduces coordination efforts and errors: integrated solution modules from the inclusion of customer requirements via the plant overview to the individual terminal together with the connected wire inside the control cabinet and all on one shared data model.

- Full control of changes and their impact due to unique tracking and revision technology.

- Secure integration of external suppliers by the convenient importing and exporting of engineering data; full change control.

- Saving time and costs with worksheets for more efficient data processing.

- Highly efficient plant configuration with clear handling of variants and options.

- Direct involvement of additional project participants accelerates cooperation and reduces coordination effort between the disciplines.

- EB Maintenance reduces time for the documentation of changes during and after commissioning.

Embedded in your company IT system

- 3-D integration for bi-directional linking of systems.

- SAP link for maintenance and service organisation.

- Open API for integration, for example, in in-house document management and maintenance systems.

- Easy Office integration for easy data exchange without proprietary interfaces.

- Integration in design systems of control engineering manufacturers to generate program code and support hardware design.